Greatest reference in our business is our successful past

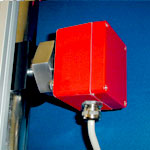

KSR PADDLE SWITCH LEVEL LIMIT SWITCHES FOR BULK

The KSR paddle switch is intended for use as

a full, empty or demand indicator.

For monitoring the level in:

Silos, bunkers, tanks, hoppers, weighing containers, containers, outlet pipes etc.

For all bulk products with a grain size of up to:

ca. 150 mm

and with apparent densities of:

0,01 to over 2,0 t/m³.

Bulk products such as:

Dusts, powders, grains, balls, granules, pellets, flat blanks, yeasts, chips, fibres, lints, feathers, seeds, roots, corms, leaves, sand, gravel, chippings and ballast. Applications in all branches of industry: chemicals, pharmaceuticals, petrochemicals, breweries, wine cellars, dairies, foodstuffs and animal feed industry, seed stores, agriculture, the paints, dyes rubber, wood and plastics industries, recycling, environmental engineering, building and building materials industry.

Temperatures of the bulk products

< 35°C.... < 500°C (depending on design)

Pressure in the container

< 0,9 bar... < 10 bar (depending on design)

Construction

The KSR paddle switch building kit with: for housings, many process connections, various arm shapes, various measuring blade sizes, allow the build up of many types of level indicator to solve all problems.

Function

The rotating measuring blade, protruding into the container, is driven by a geared motor. When the bulk product reaches the blade, it is prevented from rotating and held fast. The back torque turns the swivel mounted motor out of its end position and operates a signal switch by means of a switching arm. A second switch switches off the motor. If the filling level drops and the measuring blade becomes free, a spring moves the motor back into its original end position. This switch is the motor on the game and resets the signal switch.

Self monitoring

The self monitoring system provides early recognition of any equipment faults occurring. The following are monitored: wire breakage, voltage drop, DC/AC converter for motor voltage, motor, gearbox.

More Info

Price