* Ronan Process Monitors

Ronan Process Monitors

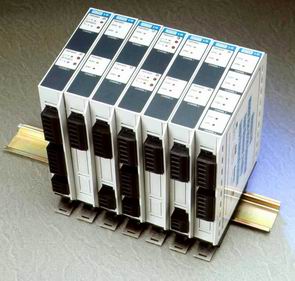

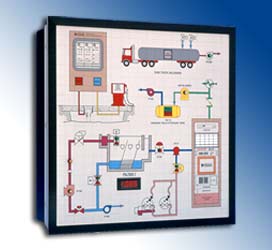

Ronan's Process Monitors are systems that include signal conditioning, alarm, digital readouts, and re-transmission of a wide variety of plant and process variables. Variables such as temperature level, flow, pressure, position, and vibration can all be monitored simultaneously from the same Ronan process monitor. These monitors are ideal as a first line of defense for critical operations, or they can provide efficient and reliable backup for alarm and shutdown functions

More Info PriceRonaan - Model X80 Process Variable Monitor/Alarm Systems

- Accepts RTD, T/C, mA, voltage and vibration input signals.

- Digital readout in deg. F, deg. C, or engineering units.

- High accuracy, resolution, and repeatability.

- Single or dual alarm and shutdown relay outputs.

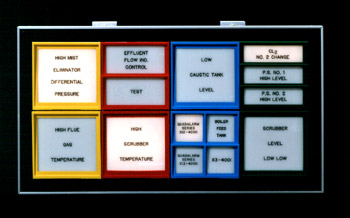

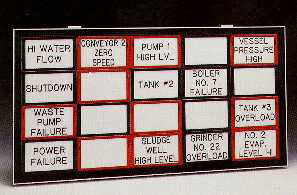

- Large engraved back-lit alarm indication windows.

- Wide variety of alarm sequences available.

- Can be grouped with conventional annunciators.

- Optional retransmission of input variables.

The X80 Series process monitor has been the workhorse monitoring system of several industries for years. The X80 can handle any of the most common monitoring needs. Plus, the easy to read engraved window alarm indications provide the conventional or classic look that many plant operators like and demand. If you need a field proven and highly reliable monitor to back up your DCS, PLC, or plant computer, the X80 systems are a perfect choice. The X80 systems can be designed to handle nearly any number of input points, and they can be made to fit almost any cabinet opening. Dual setpoint and dual input modules provide versatility and high density. Panel, surface, relay rack, or NEMA enclosure mounting options are available. Alarm sequences include automatic or manual reset with or without first-out indications.

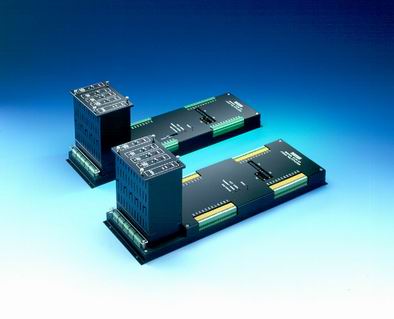

More Info PriceRonan - Model X87-- Process/Rotating Machine Monitor & AlarmSystem X87

Ronan - Model X87-- Process/Rotating Machine Monitor & AlarmSystem X87

- Inputs from thermocouples, RTD'S, mA, and voltage sources.

- Input from vibration sensors; including displacement, velocity, and acceleration.

- Continuous monitoring; no scanning used.

- Single or dual alarm and shutdown setpoints per input.

- Common Trouble, Horn, Reflash, and Shutdown relays.

- Isolated voltage or current retransmission of input signals.

- Manual reset First-Out LED alarm indicators.

- Easy to read 3.5 digit LED digital readout of input and setpoint levels.

- Key Lock Test push button to check all functions.

- High density card cage style design .

- Panel, surface, 19" rack, or NEMA enclosure chassis.

The Ronan Series X87 features continuous monitoring of temperature, vibration or almost any other process variable. The system consists of single or multiple chassis, a master module, and the required number of input modules. The master module provides digital readout of the input variables as well as each of the setpoints. The Master module also provides push buttons to test, acknowledge, and reset alarm indications. The input signals from each sensor are conditioned and scaled in the input module and continuously compared against the user adjusted setpoints. Input modules can also retransmit any portion of the measurable input range in an isolated voltage or current format. Optionally, the input and setpoint values can also be downloaded to a DCS, PLC, or plant computer via a simple RS232 interface system. The X87 complies with API 670, and is ideal for control room or field mounting in NEMA enclosures

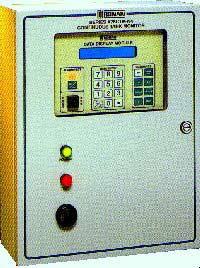

More Info PriceRonan Model X80-1052 -- Temperature and Process Monitor

Ronan Model X80-1052 -- Temperature and Process Monitor

The Ronan Series X80-1052 Temperature and Process Signal Indication System is designed to monitor temperatures from thermocouple and Resistance Bulb inputs as well as engineering units from voltage and current sensors used in industrial applications. The units may be supplied for standard flush mounting in control panels or standard EIA relay racks.

Each system consists of a master module and a number of sixteen point switch modules (up to a maximum of six) making a total of ninety-six points that can be monitored with one unit. In addition, a plug-in power supply module is available to handle 115 VAC power supply requirements. Each switch module is complete with a sixteen-point membrane-switch matrix and input signal amplifiers with interlocking electronic circuitry to prevent addressing of more than one input simultaneously.

Any given switch module accepts any of the standard RTD's, Thermocouples, or Process signal inputs. Two types of input signals can be grouped in each switch module. Therefore, 100 Ohm and 120 Ohm RTD's can be handled by the same switch module, for example, as well as, type E and J Thermocouples, or 4-20 mA and 1-5 VDC, etc.

The master module is complete with a four-digit panel meter, signal conditioning, and up to three linearizing amplifier modules. The linearization amplifier optimizes the read-out accuracy of non-linear sensor inputs such as RTD's and thermocouples. Switch modules using linear inputs require only one linearizer amplifier. Each range is achieved by adjusting zero and span on the input amplifiers provided in each sixteen-point switch module. The digital meter permits reading temperature in degrees Celsius or Fahrenheit, selectable by a front panel mounted push-button switch. Engineering Unit readouts are automatically displayed and identified with the suffix "E" on the digital display. The display can be scaled to present any readout within the digital display range.

More Info Price

.jpg)