*Ronan -Environmental Management

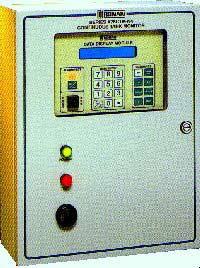

Automated Tank Monitor X76ATM

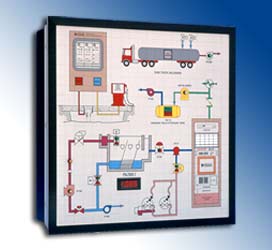

Combined with the X76ETM or X76LVCS, the X76ATM provides state-of-the-art technology to provide continuous Automatic Tank Testing without shutting down your fueling operation. The heart of the X76ATM is an embedded PC that provides the most advanced statistical tank analysis on the market today.

The X76ATM not only provides continuous statistical leak detection, but also provide the logging capability of a PC. Your facility will have a permanent record, stored on disk, to back up any test results, maintenance history, sales activity, and delivery information. These records can be reprinted by request or you can run reports from log files minute by minute as they actually occurred days, weeks, months, or even years ago. For owners of numerous facilities, the X76ATM will act as the communication link between your headquarters and the facilities.

FEATURES

- Interface to X76ETM or X76LVCS via direct serial or a modem connection

- Monthly Monitoring for 0.2 gph. No Shutdown Required

- Volumetric Tank Tightness Testing, 0.1 gph. No Shutdown Required

- Inventory Reconciliation

- Statistically Combines Multiple Tests for Higher Accuracy

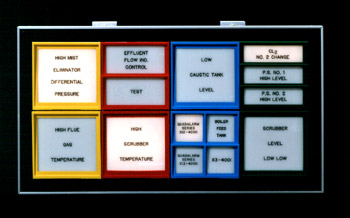

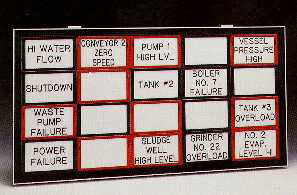

- Ronan Video Annunciator for Alarm Logging and Quick Diagnosis

- Real-Time Monitoring

- Interface to Other Leak Detection Systems

- Remote Monitoring of Equipment Not Belonging to Ronan

- UL Listed

Compliance Reporting X76CRC

The Model X76CRC Compliance Reporting Center is part of Ronan Engineering’s Wide Area Automated Facility Monitoring (WAAFM) System. Tank leak testing, alarm conditions, system status and environmental compliance data can be reported back to a central repository. Used to network multiple remote sites, the X76CRC eliminates the need for manual canvassing of facilities to obtain needed data for various regulatory agencies. The X76CRC is used to poll any or all remote X76TM2000/X76ATM’s, collect data, log and display alarm and current system status conditions to generate environmental management reports. Additionally, the X76CRC may be used as a watchdog to automatically call supervisors or maintenance companies when alarm conditions dictate. The X76CRC is part of a complete environmental management package.

Features

- Windows Based User Interface

- Centralized Regulatory Compliance Monitoring

- Automatic or Manual Remote Site Polling

- Open Database Architecture for Easy Access by Other Applications

- Historical Events Logger

- Remote Site Control

- User Defined Custom Reports

- Global Video Annunciator of All Remote Sites

Hardware Specifications

- IBM Compatible Pentium100 CPU

- 16 Megabyte Ram

- SVGA Display/Driver

- Dual 14.4 Internal Modem

- 400 Megabyte Hard Drive

- 3-1/2" Disk Drive

- Logitech Bus Mouse

- DOS 6.22

- Microsoft Windows 98, NT4.0

- Microsoft ODBC™*

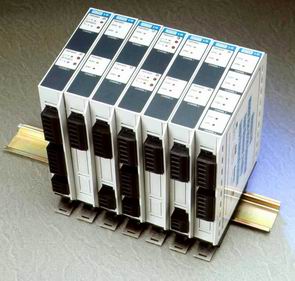

Pipe Line Preasure Sensor JT-H2

The Model JT-H2 Pipe Line Pressure Sensor is used with the X76LVC or the X76LVCS Leak Detection Systems. The Model JT-H2 does not require a mechanical regulator. This state of the art approach to the line leak detection provides the highest level of protection against leaking product into the ground for short or extended periods of time.

The Model X76DM-4B Line Leak Controler Module and JT-H2 Line Pressure Sensor monitor product supply lines for leaks greater than .05 gph. If a leak is detected, the Line Leak Module automatically shuts down the submersible pump, unlike mechanical regulators which allow continuous pumping. With a typically leak rate of 3 gph, mechanical regulators bring added clean-up costs and product loss

More Info PriceSecondary Containment Monitors X76-4X

Secondary Containment Monitors

The X76-4X offers the highest reliability for continuously monitoring secondarily contained tank and piping systems. The low maintenance and fail-safe designs, combined with a weather-tight NEMA 4X enclosure, makes the X76-4X the best monitoring solution for the harsh environments found at service stations and industrial storage tank installations.

The X76-4X provides expandable modular design with basic operator interface. Simple design, utilizing proven "C-MOS Electronics" that meets and exceeds all mil-specs, will provide years of unmatched reliability. Built to industrial control panel specifications, it affords the design engineer the option of utilizing the X76-4X as an environmental monitoring panel or a safety control panel to provide process alarms and shutdowns.

FEATURES

- NEMA-4X Weather-Tight Enclosure Ideal for Outside Aboveground Storage Tanks

- Continuous Monitoring for All Double Walled Tanks and Piping

- High and Low Level Alarms

- Positive Pump Shutdown

- Remote Alarm Capabilities

- Up to 6 Auxiliary Relays

- Flexible Modular Design for Future Expansion and Easy Maintenance

- Intrinsically Safe Interface

- UL Listed

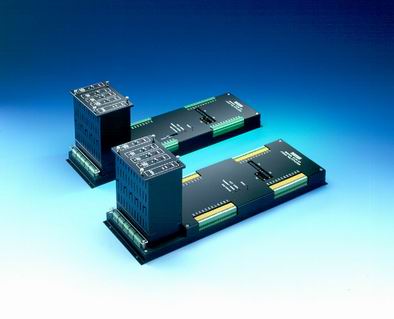

Tank Monitor 2000 X76TM2000

The Ronan X76TM2000 Environmental Compliance Software is designed for use with X76ETM-4X System. The software offers continuous volumetric tank testing and inventory management without requiring loss of revenue due to site shutdown. This state of the art software package simplifies the everyday tasks of inventory and environmental management requirements where product usage is high and frequent or periodic tank shutdown, to meet US EPA federal mandated tank leak testing, is too costly or impractical.

The Model X76ATM adds communication capabilities to the X76TM2000. This enables the X76TM2000 to communicate with the Model X76CRC Compliance Reporting Center.

Working together, the X76TM2000/X76ATM/X76CRC form the Ronan Engineering’s Wide Area Automated Facility Monitoring (WAAFM) System. The X76TM2000/X76ATM reports tank leak testing, alarm conditions, system status and environmental compliance data back to an X76CRC. Used to network multiple remote sites, the X76CRC eliminates the need for manual canvassing of facilities to obtain needed data for various regulatory agencies. The X76CRC is used to poll any or all remote X76ATM’s, collect data, log and display alarm and current system status conditions to generate environmental management reports. Additionally, the X76CRC may be used as a watchdog to automatically call supervisors or maintenance companies when alarm conditions dictate. The X76CRC is part of a complete environmental management package.

X76TM2000 Features

- Windows Based User Interface

- Precision and Continuous Leak Detection Software (CITLD) Algorithm

- Video Alarm Annunciator

- Simple and Comprehensive Inventory Management and Environmental Compliance

- Custom Report Generation

- Custom Trending

- Reconciliation

- User Password Protection

X76TM2000/X76ATM/X76CRC Benefits

- Efficient remote site compliance monitoring

- Centralized inventory management of remote sites for efficient dispatch

- Reduced cost of site maintenance

- Open Database Allows Easy Access by Other Systems

- Eliminates Manual Site Canvassing

- Custom User Designed Reports

.jpg)