* Sequence of Events Recorders NEW X500F

Sequence of Events Recorders NEW X500FT

he new Ronan X500F Sequence of Events Recorder provides the Power Generation, Power Distribution, and Process Industries with the most advanced monitoring and fault finding data acquisition system. The system's high speed, high resolution digital multiplexers utilize network interface for open and fast transmission of plant status changes to the operator on local HMI or a remote host and visual annunciators

More Info PriceSequence Etkinlik Kaydediciler X500F

Sequence Etkinlik Kaydediciler X500F

The multiplexers simultaneously store the historical event information internally, as well as a duplicate storage in the local or remote Ronan HMI software X1000 for equipment failure and shutdown analysis. The new Ronan digital multiplexer provides a user friendly network browser interface for input/output configuration, on-line alarm view, and local multiplexer history browsing.

The new Ronan Windows operating system based X1000 application software presents clear and simple event information, operator interaction, and status of all inputs via multiple split window on a single video screen display. The ability to group plant or equipment related inputs allows immediate access to the specific event information or routing to different displays/peripherals.

A complete system configuration consists of field contact termination facilities, network multiplexers, network hub(s), X500F HMI industrial computers and peripherals such as keyboards and mouse, color video, printers, and the optional window type annunciators. For critical applications the dual function SER/Visual Annunciator Systems are supplied in fully redundant configuration, where the loss of a single train does not adversely affect the information flow to the operators.

FEATURES

Multiplexers

- 128 Channel Multiplexers with Ethernet Output, GPS Time Receiver and IRIG-B Time Code Generator 200 μsec Time Resolution

- 1 msec Resolution

- Browser Interface to Multiplexer for Configuration, Event Display and History View

- Local 8,000 Event Storage

- Selectable Network Communication Protocol:

- Ronan Proprietary

- IEC60870 Over TCP/IP

- DNP 3.0 Over TCP/IP

- Single Train or Multiple Redundant Architecture

- Continuous Multiplexer Hardware/ Software Diagnostics

- Live, Logic, or Dry Contact Input (Opto-isolated)

- Input Filter - Digital, 1 to 64,000 ms Δt for Alarms, Return-to-normal and Debounce, Selectable for Each Input

- Automatic Disable/Enable of Inputs by Programmable Limit Mode

- Enable/Disable of Individual Inputs

- Periodic Front End Input Test (Automatic)

- Access Protection through Web Browser by Multi-level Programmable Passwords

Ronan HMI Software

- Grouping of Events for Video Display or Printout

- Multiple Split Window Display of Events, Operator Interaction, System Diagnostic Status, and Input State

- 500,000 Event History Storage

- NTP (Network Time Protocol) for Time Synchronization with 100 msec Resolution

- Search/Review of Event History Database

- Selective Data Printout and Screen Print

- Boolean Function Processing, Alarm Sequence Processing, and Simulator Processing

- Network Time Synchronization

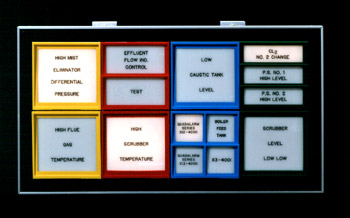

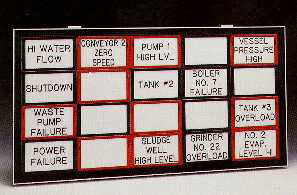

- Configurable Window Annunciator and Mimic Display Views

- Comprehensive Configuration Management Agent

- Multiplexer Distributed or Client/ Server Systems Architecture

- Open Protocols for External Host Interface

Ronan HMI Computer Hardware

- Industrial Grade, Seismic/Environ- mental Qualified, Rotating or Solid State Disk Memory, Pentium Class Microprocessor

- Single or Dual Network Interface

- Internal or Dual External Power Supplies

- Co-processor for Boolean Function Processing and Alarm Sequence Engine

- Active Relay Output for Hardware and Software Supervisory Monitoring

NETWORK HUBS

8 or 16 channel network hubs standard or switched with redundant power supply. RJ45 connector with one uplink feed.

BUILDINGS BLOCKS

Termination Facilities

The Ronan Field Termination Facilities (FTA) provide Elco 8016 connectors; four for dry contacts, and eight for live contacts. Cable assemblies, equipped with one Elco connector for connection to the multiplexer and pigtail end for connection to the customer’s existing field contact termination facilities are most commonly supplied. Ronan may supply one of a number of standard field termination facilities, or custom designed type to accommodate for special requirements. The field termination assembly typically provides for screw or compression, single or multiple output connection for interface to the multiplexers, and to digital control system (DCS), programmable logic controller (PLC), or plant computer. Additional features in standard designs are field contact isolation switches, sliding link terminals, field contact status indicators, diode gating or opto-isolators for multiple output requirements, and ground fault detection.

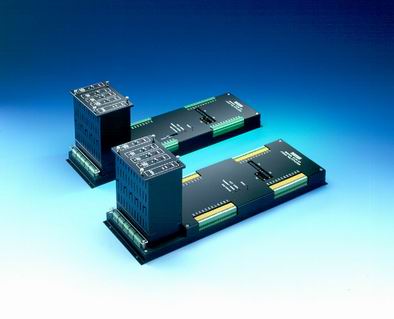

Multiplexers

The X501NET Multiplexers, designed for industrial application, are available for rackmount or surface mount NEMA (IP) enclosures. Each multiplexer houses single or dual power supplies for field contact and logic voltage capable of accepting single or dual power sources such as 115/235 Vac or 115 Vac/125 Vdc or 24, 48 Vdc. The single or dual multiplexer-controller provides for input card status interrogation, time tagging of events to 1 ms resolution, storing of up to 8,000 events, queuing of events, and transfer of events via several popular configurable communication protocols (IEC 60870, DNP 3.0, TCP/IP) over 10 Mbs 10baseT communication layer to the respective subscribers of events present on the network. Additional standard features are built in GPS time receiver with simple cable/antenna interface and IRIG-B generator output, temperature controlled precision oscillator, NTP (Network Time Protocol) for backup synchronization and complete web server for simple browser interface configuration and monitoring facilities. Up to 8,000 local event data storage, hardware/software diagnostic, field contact input test with an option that includes the opto-isolator input circuit. The sixteen input modules, each serving eight input contacts, are microprocessor controlled for input status interrogation, status change queuing, digital filters by individual inputs for alarm, return-to-normal, debounce, and normally open/normally closed field contact logic. This multiplexer is a self-sustained event acquisition, recorder, and producer unit.

Network Hubs

The network hubs, available in sixteen channel rackmount or eight channel surface mount, are utilized to place network devices such as multiplexers, HMI computers and Ronan X110NET Serial Annunciator on to a common network segment while providing complete physical isolation and switched port design chatter suppression for a much higher network integrity system. The chassis design features rugged industrial packaging with single or dual power source such as 115/230 Vac, 50/60 Hz, or 24, 48, or 125 Vdc.

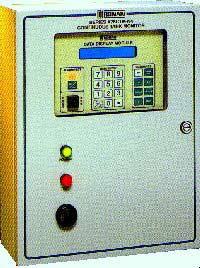

HMI HARDWARE/SOFTWARE

Ronan Industrial Computer

The X500F Industrial Grade Computer is available in table top or rack mount design, tested for high level of Seismic application as well as RFI/EMI susceptibility requirements. Internal power supply for single source application, solid state memory, the CPU module, based on a Pentium class processor (upgradeable to higher performance CPUs). The computer is also available with external power supply for dual power source input, such as 115/230 Vac, 50/60 Hz or 24, 48, and 125 Vdc. A compact 1U configuration (1-3/4” high) computer is also offered for less critical applications. A complete HMI computer is offered with rack mount or table top housing, color L.C.D. for video display of available sizes, Color Dot Matrix printer for alarm/report printout, and color laser printer for custom color report printing. The printers are offered as dedicated serial printers or network printers depending on the system’s architecture.

X500F SOFTWARE (X1000)

HMI (Human Machine Interface)

The Ronan X500F Sequence of Events Recorder is provided with several different versions of highly integrated, Windows based operator interface software uniquely designed to suit different applications and system complexities.

X1000 Integrated

This Windows based application is generally used with small and large systems where all equipment is connected to a single network segment and applications requiring local database of sequence of events as well as redundant data acquisition needs. The main software task is to provide, in clear and concise format of the event data, event storage, operator action, system’s health, and current state of the field contacts. Software access is comprehensively password protected for different levels of users with different access rights and privileges. The system is ideally suited for remote sub-stations, switchyards, power and process monitoring. The software provides configuration database for selection of normally open/normally closed field contact logic, filter parameters, display parameters, alarm sequences, network connection and user rights and group assignment. All event data is stored in the rigid disc or solid state memory. The historical information of up to 500,000 events may be reviewed on the screen in its entirety or queried with specific parameters for an accurately sorted display of information or hard copy. The new flexible Windows user interface event information is displayed in an event windows format which is user configurable. System messages use a second window. The system’s time is continuously synchronized via NTP client receiving time data from an NTP server.

X1000 Server/Database/Client

This group of software is specifically designed to provide a client/server architecture through the use of system network. The software consists of clients user interface application and producer server/database for central-remote data acquisition application. A typical application of the software is to continuously gather accurate 1 msec resolution event data from many remote locations into a central data repository location via dedicated Ethernet network structure or public Internet connection (Broadband). The software package X1000 consists of one or more client user interface software which is similar to the Ronan standard integrated software. Producer software is provided as one of the components of the central server software that accompanies a third-party licensed database software. The central station is provided with a GPS synchronized network time server that communicates to all network time clients inside each multiplexer and X1000 software via NTP protocol, providing an accurate system time synchronization.

REPORTS

The X500F system provides hard copy printout of all recorded data at the operator’s request. Reports such as Current Alarms, Event History, Message History and Legends are generated and printed as needed. The application query feature allows sorting of stored data by any one record, or a combination of records in logical order. The system then allows easy print out of queried data as seen on the screen to a report printer on the network. The application uses all of the advanced features of the Windows operating system print functionality for printing.

PERIPHERALS

Videos — A wide variety of color LCD or CRT monitors is available for use with X500F HMI systems. Various resolutions and sizes are available for table top, panel or rack mounting.

Printers — Various color or black and white serial or network printers are available for report or alarm printing. Industrial grade impact printers are also available with 80 or132 characters wide for continuous alarm printing.

Serial Input Visual Annunciators — The X500F system has the ability to send serial events via the network to X110 NET Ronan serial network annunciator for visual annunciation on all Models of the Ronan lamp cabinets.

Host Connectivity — The Ronan network multiplexers provide host connectivity via IEC 60810, DNP3 and Ronan proprietary protocol to host device.

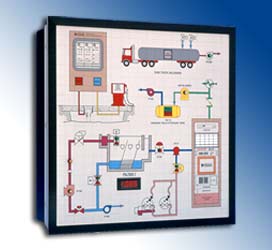

Plant Process Monitoring

The X500F basic system configuration consists of field contact termination facilities, network multiplexers, network hub, HMI computer unit including the support modules based on system requirement, a color monitor, and one or more serial or networkable printers. The field termination facilities are connected to the multiplexers via multiple conductor cable assemblies. The network cat5 10baseT cable is connected to a central hub which is connected via similar cable to the computer’s network module hosting the Ronan HMI software. The system may, optionally, provide input status information to the Ronan network X110 NET serial input visual annunciator.

Dual Train Redundant System

For critical applications such as nuclear or conventional power plants, petro, petro chemical or chemical processes, the system may be configured in dual redundant trains. To achieve highest reliability and MTBF requirements for this type of requirements, all equipment is duplicated to provide two complete trains, connected via two networks, to the HMI computers which provide output to the color video and printer(s). Optionally, the system may provide input status changes to a redundant network serial input visual annunciator. All host interfaces are connected via the network hub.

Remote Monitoring/Event Recording With Central Data Acquisition - Management

Multiple site SER systems typically utilized in power distribution and switchyard applications require transfer of event information and site input configuration to and from a central master station. These remote SER systems are connected to the master station via dedicated Ethernet network or Broadband network. Ronan utilizes a client/server architecture using several different TCP/IP based protocols such as IEC-60870, Ronan proprietary protocol to communicate between remote sites and central station. Clients reside in each multiplexer with its own dedicated IP address and connect to the central server/producer. All remote input configuration can be set up from the master station server application. Optionally, a local HMI display and data recorder is available at each remote SER site with its own display and CRT for local monitoring and maintenance. Real time synchronization between multiple remote sites and central site for area wide synchronization is achieved by GPS (Global Positioning System) signal feed to each multiplexer and at central site through a GPS receiver/network time server.

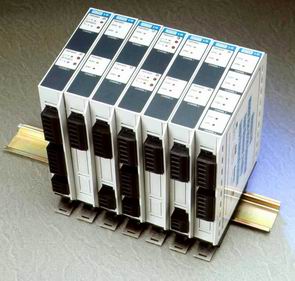

Sequence of Events Recorders X500E

Sequence of Events Recorders X500E

The X500E Sequence of Events Recording System provides Utilities and Process Industries with the most advanced event monitor and fault finder.

The System’s high speed, high resolution digital data acquisition capability provides for instant display of plant and equipment status changes on color videos, printers, and window annunciators in the Control Room.

Large historical event information (500,000 events) provide for concise and selective analysis of plant shutdowns or equipment failures.

The X500E System’s architecture allows to configure single train to fully redundant network and hardware based systems to meet specific custom requirements.

The Systems can provide or receive real time synchronization via IRIG-B signal from GPS or Time Code Generator.

.jpg)