*Ronan-Single or Double Wall Line Monitor

Alarm Cont. Input Module X76AM-4

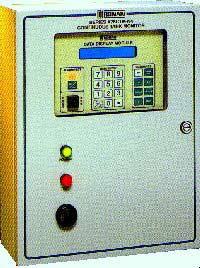

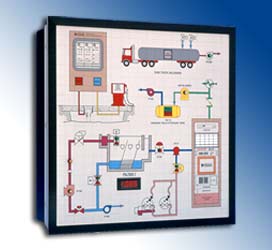

Electronic Tank Monitoring System

Ronan’s Electronic Tank Monitoring Systems assure you of accurate and dependable performance no matter what your application – fuel inventory, in-tank leak detection, product line leak detection, secondary containment monitoring or vadose and ground water vapor sensing. The heart of the Series X76ETM System is a unique memory chip which will not lose program information or reports even when power is shut off. Combining an on-board printer, a membrane keypad and an LCD display, the X76ETM is a system easy to operate and simple to understand.

In addition to simple operation, the X76 Electronic Tank Monitoring System provides advantages because of two onboard telecommunication interfaces. This advanced technology allows you to schedule timely bulk deliveries and provides the convenience of hardcopy accountability of monitor status and EPA required inventory reports.

The X76 ETM System also offers a two-fold safety net. Programmable start/stop times for the Leak Detect mode allow underground storage tanks to be automatically tested every day during the hours the station is closed. The Leak Detect Report can furnish government officials with a "PASS/FAIL" summary of test results. What’s more, the system includes eight auxiliary input contacts to monitor other external vapor or liquid detection systems. Multiple output relays for external alarms or system integration, such as automatic shut-off, are standard.

Features

- Tank Inventory up to Eight Tanks

- Tank Leak Testing

- Product Line Leak Testing

- Ground Water and Vapor Well Monitoring

- High and Low Level Alarm Monitoring

- Secondary Containment Monitoring

- Modular Design for Maximum Reliability

- Double-wall Pipe Monitoring

- Dry Contact Inputs

- Intrinsically Safe Interfaces

- Remote Alarm Capabilities

- Dual RS-232C Interface

- Dry contact Alarm Outputs

- Triac Alarm Outputs

- Battery Backup

- Non-volatile Memory

- 316SS Chemical Probes

Horizontal Liquid Sensor Model LS-7

Ronan Engineering’s Models LS-7s and LS-7s Horizontal Liquid Sensors are designed to detect the intrusion of liquid in dry interstice double wall fiberglass tanks, containment zones and caisson compartments where horizontal positioning of the sensor is preferred. The integral Pull-to-Test cable on the LS-7s, required in some jurisdictions, allows sensor testing from ground level. Constructed of PVC the LS-7 and LS-7s will provide years of trouble-free service.

The LS-7’s unique design cannot be installed upside down as is the case with sensors from other manufacturers. Liquid collection sufficient to raise the sensor float will transmit a signal to the control panel to initiate control functions or annunciate alarms.

The LS-7’s thin cross section makes it ideal for applications where limited vertical clearance is available. The sensor may be installed in any horizontal application where there is 0.625 inches of vertical clearance.

Typical Applications

- Double Wall Fiberglass Tank Dry Interstice Monitoring

- Double Wall Piping Containment Sumps

- Horizontal Application Point Level Sensing

- Restricted Vertical Clearance

- Where Ground Level Testing is Required

Ronan’s LS-7 Sensor operates on a direct principle. A glass encapsulated, hermetically sealed, reed switch is embedded within the sensor body. A permanent magnet in the sensors float creates a magnetic field which surrounds the reed switch holding the switch closed. When the magnetic field is removed by moving the float, the reed switch is actuated, thereby changing state. This condition opens a closed switch. This change in state is then signaled to the control panel.

Specifications

- Wetted Parts: PVC (Geon 87241)

- Installation: Horizontal, 0.635 inch minimum vertical clearance

- Switch Rating: SPST 10VA, 120-240Vac pilot duty

- Temperature Operating -40ºF to +140ºF

- Liquid S.G.: 0.70 minimum

- Pressure: 50 psi maximum

- Cable: PVC jacket, twisted pair, 20AWG, 25 ft

Hydrostatic Resev. Sensor LS-30

Ronan Engineering’s Model LS-30 Hydrostatic Reservoir Leak Sensor is designed to detect changes in liquid level within reservoirs of hydrostatic monitored double-wall tanks. Constructed of 304 stainless steel, polysulfone, Beryllium Copper and PVC, the LS-30 will provide years of trouble free service.

Typical Applications

- Double Wall Fiberglass Tank Reservoir Monitoring

- Low and Low Low Level Monitoring

- High Level/Overfill Monitoring

- Vertical Application Dual Point Level Sensing

The LS-30 can be installed to provide discrete indications of liquid increase or liquid loss, or provide high or low liquid indications. A breach of the tanks inner wall will allow reservoir liquid to escape the interstice into the primary tank, and a reservoir level drop will occur. A breach of the outer tank wall will allow reservoir liquid to escape the interstice into the environment, or ground water to enter the interstice, and a reservoir level change will occur. Liquid increase or loss, sufficient to move the sensor’s float will transmit a signal to the control panel to initiate control functions or annunciate alarms.

Ronan’s LS-30 Sensor operates on a direct principle. Glass encapsulated, hermetically sealed, reed switches are embedded within the sensor stem. Permanent magnets within the sensor floats create a magnetic field which surrounds the reed switches. When a magnetic field is removed by movement of one or both floats, the reed switch is actuated, thereby changing state. This condition either opens a closed switch or closes an open switch. This change in state is then signaled to the control panel.

The LS-30’s design allows rigid or flexible mounting for easy periodic testing as required by many regulatory agencies. The sensor may be mounted loosely suspended by its cable, or rigid with the 1/2 inch NPT nipple. The LS-30 may also be supplied with the optional RC-4 four inch riser cap assembly. The LS-30 is supplied with the low circuit N.O. and the high circuit N.C. Other logic configurations are available by specifying at time of order.

Specifications

- Wetted Parts: 304 and 316 Stainless Steel, Beryllium Copper, Polysulforne, PVC

- Mounting: 1/2" NPT, male

- Switch Rating: SPST, 20VA, 120-240 Vac pilot duty

- Operating Temperature: -40ºF to +225ºF Temperature:

- Float S.G.: 0.65

- Pressure: 75 psi maximum

- Cable: PVC jacket, 2 twisted pair, 20AWG, 15 ft

Leak Detection System X76LVC

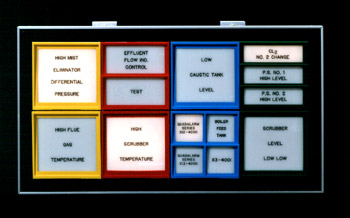

The Series X76LVC is designed to monitor liquid level, vapor density, pressure and hydrostatic pressure. The system generates an alarm and may shut down specific facilities if preset parameters are exceeded. The microprocessor based system provides visual and audible alarms, self-diagnostics and sensor failure indication, fail-safe shutdown and auxiliary switch outputs for communications to a facility’s remote displays.

The liquid level sensors will indicate presence of liquids in the annular space of double-wall tanks, secondary containment pipes, manhole or caisson compartments and in-tank high level to prevent overfill. The vapor density, measured by the product’s unique vapor transducer, is indicated on the appropriate plug-in module in parts per million (ppm) by means of a 4½ digit LED display. The display not only indicates the initial background vapor density in a vadose well or the annulus of any secondarily contained vessel, but also monitors an increasing trend of vapor density. The self-contained display also provides the ability to set the alarm and shutdown setpoints without additional calibration equipment.

The pressure measurement utilized to monitor pressurized supply piping reads the pressure decay caused by a leak rate greater than 0.1 gph occurring between automatic test cycles.

A hydrostatic measurement is applied to the annulus of a double-wall tank by detecting a loss of pressure in the pressurized cavity or the loss of liquid level in a reservoir or the annulus of the tank. The X76LVC System, housed in an attractive wall mounted NEMA Type 1 Enclosure, contains the intrinsically safe barrier interface to the transducers, a number of three channel alarm modules, vapor modules, and/or dispenser modules. The front door mounted audible alarm and the flashing alarm lights are acknowledged by the ACK button and functionally tested by means of the TEST push button

More Info PricePressure/Vacuum Sensor JT-2P and JT-2V

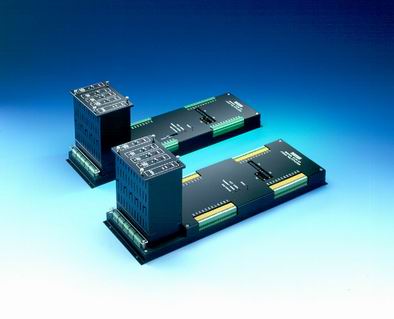

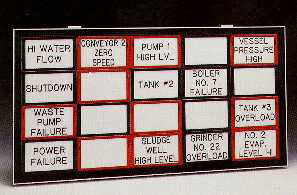

Underground Storage LD System X76S

Leak Detection System

The model X76S Leak Detection System continuously monitors underground storage tank installations for leakage of gasoline, diesel oil, waste oil and other hydrocarbons.

Two types of Liquid Level Sensors are horizontally or vertically positioned in the normally dry annular space of double-walled tanks. Upon accumulation of product due to a leak, the sensor will provide an audible and visual alarm.

Hydrostatic and air pressure sensors can provide monitoring of both the outer or inner shell of a double-wall tank.

The sensor’s outputs are continuously supervised by individual alarm modules via FM approved intrinsically safe barriers. This allows installation of the sensors in Class I, Division 1, Groups C, or D areas as defined in the National Electrical Code, without using costly conduits, conduit seals and explosion proof junction boxes.

The X76S provides up to four sensor alarms.

Features

- Up to 4 Input Modules with LED Indicators

- Audible and Visual Alarms

- Intrinsically Safe Interface to Sensor

- Field-Proven Circuit Design

- Liquid Level Sensors: High Reliability, UL Listed, Compatible with Hydrocarbons, Maintenance Free

- Alarm Contact Output per Sensor for Remote Indication, Telemetering, or Positive Shutdown

- Hydrostatic Leak Detector for Double-wall Tanks

- Positive Pressure Sensor for Pressurized Double-wall Tanks

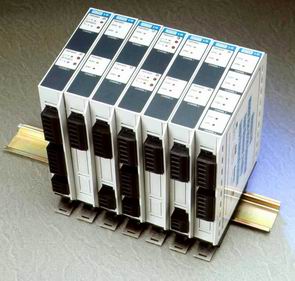

Vertical Liquid Sensors Models LS-1 and LS-3

Ronan Engineering’s Models LS-1 and LS-3 Vertical Liquid Sensors (and the variations LS-3s and LS-3ss) are designed to detect changes in liquid level within reservoirs or the intrusion of liquid in dry containment zones and caisson compartments where vertical positioning of the sensor is allowed. Both the LS-1 and the LS-3 are constructed of 304 and 316 stainless steel, polysulfone, Buna-N and PVC. The LS-3s includes an integral Pull-to-Test cable, required in some jurisdictions. The LS-3ss Sensor is constructed of 304 and 316 stainless steel and Teflon, and is designed for use in chemical applications where corrosion is a concern. All LS-3 sensors are designed to provide years of trouble-free service.

Typical Applications

- Double Wall Steel Tank Interstice Monitoring

- Piping Containment Sumps

- Sub-pump Containment Sumps

- Fill Riser Containment Sump

- High Level/Overfill Monitoring

- Vertical Application Point Level Sensing

- Where Ground Level Testing is Required

- Corrosive Chemical Monitoring

All LS-1 and LS-3 sensors have user selectable logic and may be installed in wet or dry conditions. Liquid collection or loss, sufficient to move the float will transmit a signal to the control panel to initiate control functions or annunciate alarms. The sensor’s design allows rigid or flexible mounting to allow easy periodic testing as required by many regulatory agencies. The sensor may be mounted loosely suspended by its cable or rigid with the 1/2 inch NPT nipple.

Ronan’s LS-1 and LS-3 Sensors operate on a direct principle. A glass encapsulated hermetically sealed reed switch is embedded within the sensor stem. Permanent magnets within the sensors float create a magnetic field which surrounds the reed switch holding the switch closed. When the magnetic field is removed by movement of the float, the reed switch is actuated, thereby changing the state. This condition either opens a closed switch or closes an open switch. This change in state is then signaled to the control panel.

Specifications

- Wetted Parts: 304 and 316 Stainless Steel, Buna-N, Polysulfone, PVC, Teflon

- Mounting: 1/2 inch NPT, male

- Switch Rating: SPST, 20VA, 120-240 Vac pilot duty

- Operating Temperature: -40ºF to +180ºF (LS-3 & LS-3s), -40ºF to +300ºF (LS-3ss)

- Float S.G.: 0.55 (LS-3 & -3S), 0.77 (LS-3ss)

- Pressure: 150 psi maximum (LS-3 & LS-3s) 400 psi maximum (LS-3ss)Cable: PVC or Teflon jacket, twisted pair, 20AWG, 22 ft

.jpg)