Gebr. Steimel GmbH & Co.

|

PUMPS |

|

Pumping medium palette |

|

Magnetic coupling drives |

|

ATEX types |

|

Special designs |

|

Type T |

|

Type TF |

|

Type SF |

|

Type GMB |

|

Type PK |

|

Type SKK |

|

Type MZ, KZ, KB |

Pumps

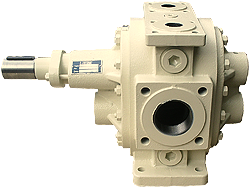

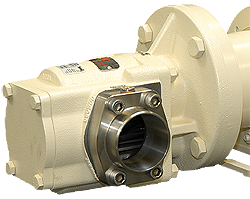

Gear pumps Type T: 15 - 1,800 cm³ / rev., up to 16 bar, up to 80,000 mm²/s

Gear pumps Type TF: 80 - 1,000 cm³ / rev., up to 25 bar, up to 50,000 mm²/s

Gear pumps Type SF: 2 - 1,000 cm³ / rev., up to 10 bar, 5 to 50,000 mm²/s

Gear pumps Type GMB: 3 - 20 cm³ / rev., up to 25 bar, up to 5,000 mm²/s

Gear pumps Type B: On request still available - please contact us!

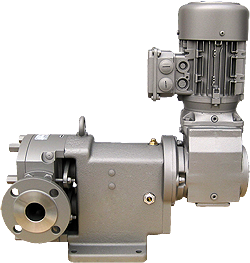

Rotary-lobe pumps Type SKK: 60 - 3,400 cm³ / rev., up to 20 bar, up to 100,000 mm²/s

Hygienic pumps Type HKK: NEW - Hygienic rotary-lobe pumps

Centrifugal pumps Typs K + M: Motor- and cooling-water pumps

Centrifugal pumps Type KB: On request still available - please contact us!

Centrifuges

POLAR C: up to 300 kg/batch, up to 200 Liter/batch, up to 12 batches/hour

POLAR F: up to 300 kg/batch, up to 200 Liter/batch, up to 30 batches/hour

POLAR FK: swiveling, up to 300 kg/batch, up to 70 Liter/batch

POLAR Z: Special centrifuge for spinning off galvanized parts

PERMOLEX-POLAR K: continuous working centrifuge, up to 10 m³/hour

HYDRO-POLAR E: up to 300 kg/batch, up to 120 Liter/batch, up to 10 batches/hour

HYDRO-POLAR ZST: especially for grinding sludge, up to 40 L/batch, up to 6 batches/hour

KIPP-POLAR ZAU: swiveling, up to 70 Liter/batch, up to 10 batches/hour

CAPA-POLAR ZBL: the coating-centrifuge

ROBOT-POLAR System: the automatic system for swarf- and parts-treatment

SCHOKO-POLAR System: for REWORK processing in the chocolate-industries

Swarf crushers

Swarf crushers RS: up to 8 t/hour

Swarf crushers RS K: the compact, up to 500 Liter/hour

Swarf crushers RS T: the specialist, up to 200 Liter/hour

Swarf conveyors

Scraper conveyor KF: up to 8,000 Liter/hour

Hinged belt conveyors SF: up to 9,000 Liter/hour

Industrial pumps

We offer pumps in the following structural shapes

Gear pumps ( types T, TF, SF ), gerotor engine-block pumps ( type GMB ), rotary lobe pumps ( type PK ), rotary piston pumps ( type SKK ), centrifugal pumps ( types MZ, KZ, KB ), ...

as feed pump, lubricating pump or engine cooling-water pump

In accordance with ATEX any pump type can be delivered!

We regard ourselves as partners who find solutions to individual requirements!

Selection from the range of pumping media

If you don't find your application here we are pleased to advise you.

Products for the chocolate and sweets industry

chocolate-centrifuge

SCHOKO-POLAR

The chocolate-centrifuge

SCHOKO-POLAR Type 8

is an industrial centrifuge for the separation solids, such as nuts, biscuits, raisins etc. and chocolate masses.

Advantages

- compact construction in three sizes

- technically perfected with high efficiency and best operation security

- simple cleaning

- drum construction according to customer‘s wishes

- automatic sequence of operations

Typcal applications: REWORK

During the production of chocolate products with solids, such as nuts or biscuits, goods are produced that can not be sold to the customer. A typical example are broken biscuits. A biscuit coated with chocolate that has broken into pieces during production, can no longer be sold and still the chocolate has a certain value for the manufacturer.

The chocolate is now very economically and most efficiently reused by the use of the SCHOKO-POLAR centrifuge, as it is separated from the biscuit and sent back to the manufacturing process. For these and similar applications this type of centrifuge has been designed.

Description

The centrifuge casing is made of stainless steel (1.4301). All surfaces coming into contact with the product on the inside of centrifuge are electropolished and thus guarantee best flow properties of the spun-off product, such as chocolate.

The special centrifuge motor has a stepless speed control.

The centrifuge has two heating systems. First an adjustable hot air blower heating is used to heat the filling material via an opening in the centrifuge cover so that e.g. the chocolate mass is liquified. Secondly, the machine has a jacket heating with an adjustable hot water circulation. This heating esures that the spun-off liquid mass does not become hardened at the cold jacket surface but remains liquid during the spinning-off process.

Technical data

|

|

SCHOKO-POLAR 4 |

SCHOKO-POLAR 6 |

SCHOKO-POLAR 8 |

|---|---|---|---|

|

*Depending on the preset parameters. |

Modifications reserved. |

||

|

Drum diameter |

400 mm |

600 mm |

800 mm |

|

Drum height |

260 mm |

385 mm |

540 mm |

|

max. filling volume |

18 L |

70 L |

190 L |

|

max. filling weight |

50 kg |

150 kg |

150 kg |

|

max. speed |

980 r/min |

980 r/min |

735 r/min |

|

number of cycles / h max. * |

8 |

8 |

8 |

chocolate-pumps

The gear pumps

gear pump Type TM

with heater jacket

gear pump Type SF

without heater jacket

of the type TM and SF are industrial pumps with/without heatable jacket for the transport of e.g. cocoa mass, cocoa butter, chocolate mass, sugar mass, fat, licorice, food oil, syrup and many more.

Advantages

- pulsation-free pumping delivery

- rotation independent

- sturdy construction

- easy to assembly

- completely closed heater jacket

- heatable with water, steam and thermal oil

- heating temperature depending on agent

- up to max. 320 °C - DIN-flanged, milk pipe, SAE or threaded connection

Reference technical data

- feeding capacity 2 - 1,800 cm3 / turn

- permitted overpressure up to 16 bar (higher pressures on request)

- viscosity range up to 80,000 cP

Materials

- grey cast iron

- bronze

- stainless steels

Seal types

- packing

- mechanical seal with simple effect and with double effect (with retaining pressure)

- radial shaft seal

- magnetic coupling (depending on agent, hermetically closed)

The rotary piston pumps

rotary piston pump type SKK

of the type SKK are industrial pumps with/without heatable jacket for the transport of e.g. cocoa mass, cocoa butter, chocolate mass, sugar mass, fat, licorice, food oil, syrup, honey, jam, dough mass, puree and many more.

Advantages

- rotation-independent

- safe to run dry (no metal contact)

- sturdy construction with one-sided bearing

- easy assembly

- DIN-flanged, milk pipe, SAE or threaded connection

- casing with cover heating

- entirely closed heater jacket

- heatable with water, steam and thermal oil

- heating temperature depending on agent

- maximum 200 °C

- higher temperatures on request

Reference technical data

- feeding capacity 60 - 3,200 cm3 / turn

- permissable overpressure depending on application up to max. 20 bar

- viscosity range depending on application up to 100,000 cP

Materials

- grey cast iron

- bronze

- stainless steels

Seal types

- packing

- mechanical seal with simple effect and with double effect (with retaining pressure)

- radial shaft seal

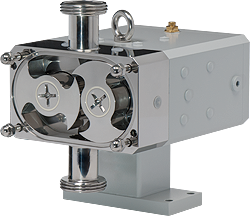

The newly developed HKK hygienic rotary lobe pump

HKK hygienic rotary lobe pump

HKK hygienic rotary lobe pump

is based on the construction of the successful SKK rotary lobe pump. It was developed especially for use in the food industry and supplements the range of the pump models from Gebr. Steimel GmbH & Co. by this hygienically very sensitive area.

The pump is currently undergoing certification in the Weihnstephan research centre for brewing and foodstuff quality at the TU (Technical University) in Munich.

All application-relevant aspects flowed int the construction of the HKK. All parts coming into contact with the product were optimised according to hygienic design aspects and a pump is therefore available that covers the typical requirements of the user in the food industry.

Approval and market introduction is expected in spring 2013.

Advantages

- In EHEDG certification

- CIP and SIP capable

- Perfect for drinks and foodstuffs

- From low to highly viscous

- Hygienic, gentle conveying

- Abrasion free

- Available completely in stainless steel

- Pressure relief valve can be integrated

- Aseptic connections according to DIN 11864

- Easy replacement of the seals

- Independent of rotation direction

Typical fluids

Dairy products (eg yoghurt, fruit yoghurt, quark, cheese), oils, fats, soups, sauces, confectionery, fruit preparations, fruit juices, etc.

Gebr. Steimel GmbH & Co.

Gebr. Steimel GmbH & Co. Ürünleri ile uygun rekabetçi fiyatları almak için müşteri temsilcimiz ile http://www.imajteknik.com.tr/bize-ulasin veya Fiyat teklifi formunu doldurarak mesaj bırakmanız halinde satış muhendislerimiz en kısa zamanda sizinle irtibat kuracaklardır.

Gebr. Steimel GmbH & Co. hakkında daha fazla bilgi için tıklayınız.